CBILS®

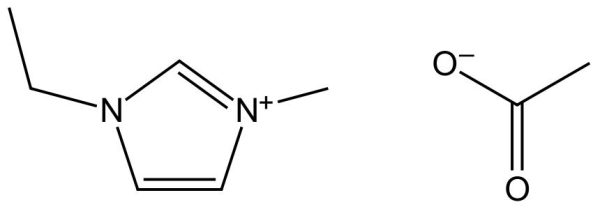

Carbonate Based

Ionic Liquid Synthesis

CBILS®, a unique Ionic Liquid production technology for waste-free, safe and economic production of ultra-pure ionic liquids.

CBILS® - Our toolbox for your Ionic Liquid

Halide-free technical synthesis of Ionic Liquids with consistent quality

One of the most advanced commercialized methods for the industrial production of high-purity ionic liquids is the Carbonate Based Ionic Liquid Synthesis process. CBILS® is a registered trademark of proionic GmbH. This entirely halide and waste-free production route uses carbonic acid esters as quaternization reagents. This process overcomes most of the drawbacks of conventional synthetic approaches and keeps the use of noxious chemicals to a minimum.

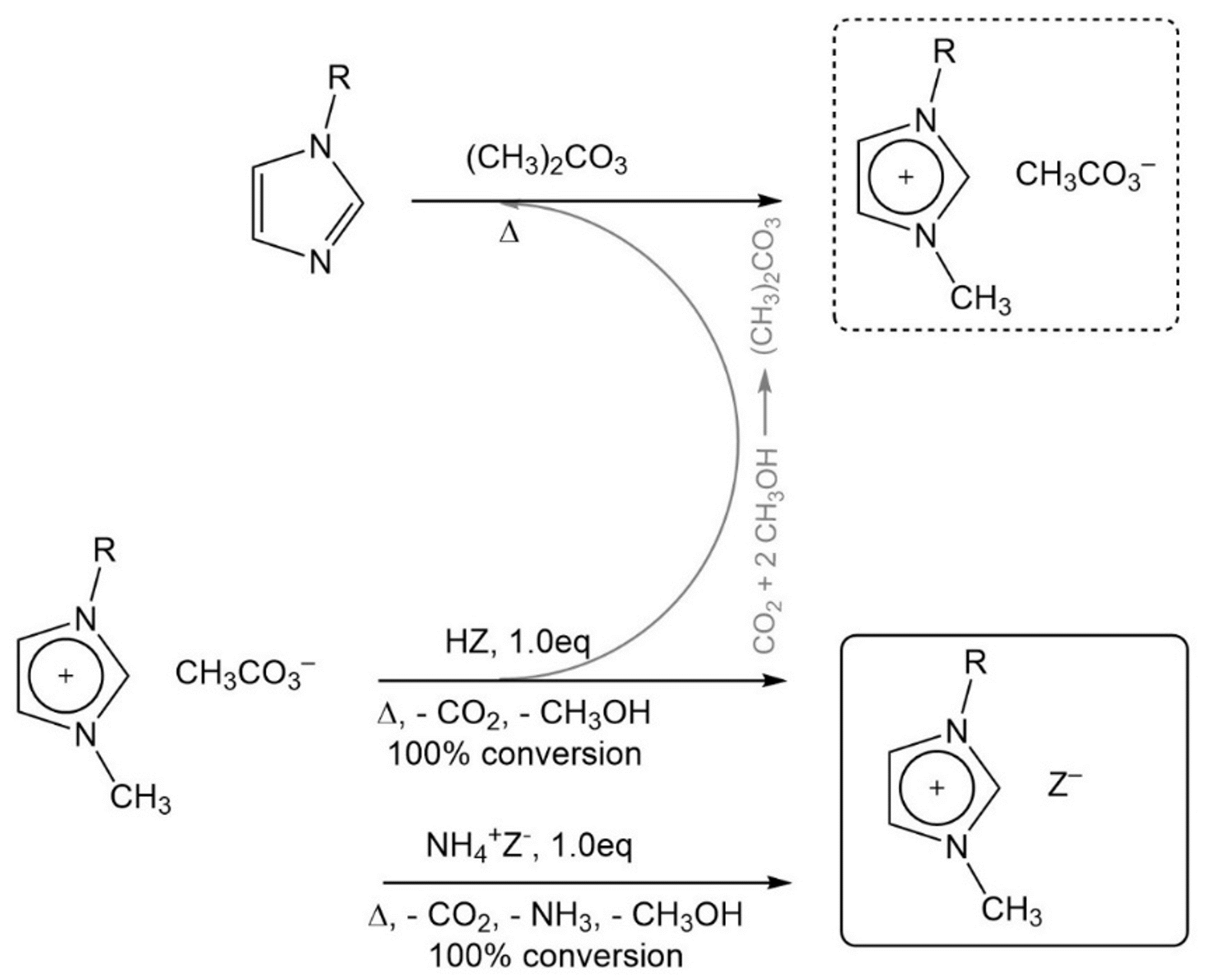

General concept of the CBILS®-route

Virtually unlimited combinations

Standard Ionic Liquids

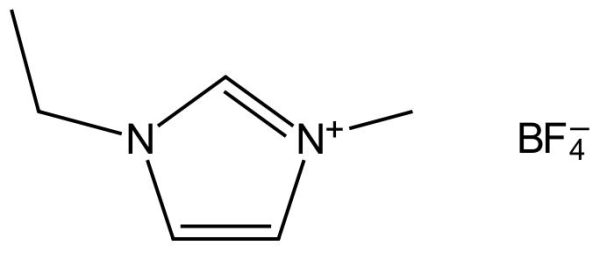

proionic’s powerful CBILS® ionic liquid production process enables a virtually unlimited combination of cations and anions. Choose your cations and anions from a list of standard ions and put together the desired ionic liquid in a modular system according to your needs.

Tailormade Ionic Liquids

You cannot find the desired Ionic Liquids in our Ionic Liquid Catalog? We will be happy to help you with your specific Ionic Liquid.

Key benefits

01

halide free

The halide content of CBILS® Ionic Liquids is less than 5 ppm.

02

low water content

Water levels in ionic liquids below 20 ppm are achieveable on large scale.

03

perfect cation-anion stoichiometry

The cation-anion stoichiometry is easily adjustable.

04

no waste

High atom economy is given as no waste is generated during production.

05

high product quality

Except for the distillation of solvent residuals, no further purification of products is necessary.

06

scale-up to ton level

The robust production process can be easily translated to a multi ton level.

Further information on the CBILS® process

Modular System

The CBILS® methylcarbonate intermediates are converted quantitatively to the final IL upon reaction with every Brønsted acid having a pKa <9.

High process robustness

High batch to batch stability and continious ultra pure quality.